Biodiesel (HVO/HEFA)

HVO: Second generation biodiesel, also known as Renewable Diesel. On the basis of the first generation, it underwent hydrogenation deoxygenation and isomerization treatment, known as hydrogenated deri

HVO: Second generation biodiesel, also known as Renewable Diesel. On the basis of the first generation, it underwent hydrogenation deoxygenation and isomerization treatment, known as hydrogenated deri

HVO/HEFA: Second generation biodiesel, also known as Renewable Diesel. On the basis of the first generation, it underwent hydrogenation deoxygenation and isomerization treatment, known as hydrogenated derived renewable diesel or hydrogenated vegetable oil (HVO). It has similar viscosity and calorific value to diesel, lower density, higher cetane value, lower sulfur content, good stability, and is in line with the development direction of clean fuels. Compared to the first generation biodiesel, the second generation diesel can be mixed with regular diesel in any proportion, and after processing, it can even replace traditional aviation kerosene. At present, second-generation biodiesel is developing rapidly in the United States and Europe. According to the 2020 Global Renewable Energy Report released by REN21, the global proportion of second-generation biodiesel in Europe and the United States in 2019 was 44.6% and 38.5%, respectively.

Hydrogen based biodiesel production process:

Firstly, extracting oils from vegetable or animal fats requires pre-treatment such as screening, impurity removal, and dehydration.

Then, the raw oil or fat undergoes hydrogenation reaction under the action of high pressure, high temperature, and hydrogen catalyst. This process will convert the saturated and unsaturated fatty acids in the raw materials into longer alkyl chain molecules. By controlling the reaction conditions and the type and concentration of catalysts, it is possible to ensure the production of high-quality HVO biofuels.

Finally, after the hydrogenation reaction, impurities and odors may still exist in HVO biofuels. In order to improve the quality and stability of fuel, it is necessary to carry out decolorization and deodorization treatment. This process typically involves the use of adsorbents and steam methods to remove unnecessary components and improve fuel purity.

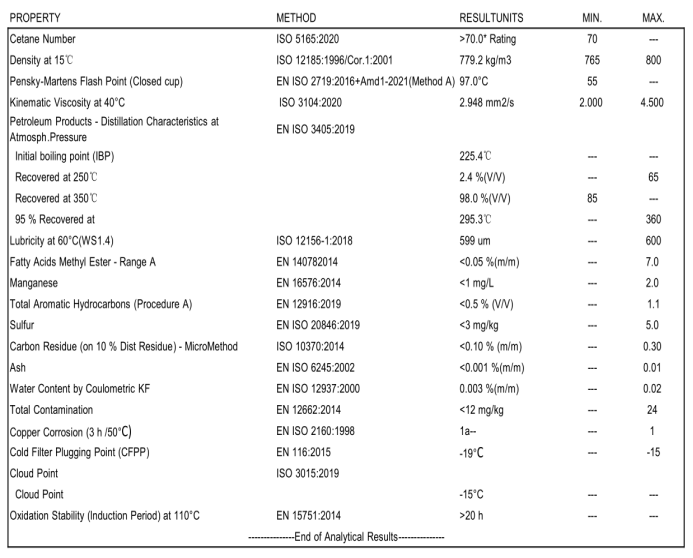

Quality Index:

+86 19113264742

Room G755, Office Building 2, Bonded Port Area, Xinying Bay District, Yangpu Economic Development Zone, Hainan Province.

09:00-18:00