Used Cooking Oil (UCO)

The chemical name of "Used Cooking Oil" is fatty acid triglyceride, which is refined from used cooking oil (commonly known as ground oil), brine oil, and other raw materials. It can be used

The chemical name of "Used Cooking Oil" is fatty acid triglyceride, which is refined from used cooking oil (commonly known as ground oil), brine oil, and other raw materials. It can be used

The chemical name of "Used Cooking Oil" is fatty acid triglyceride, which is refined from used cooking oil (commonly known as ground oil), brine oil, and other raw materials. It can be used as biodiesel raw materials, Aviation fuel raw materials, plasticizer raw materials, oleic acid raw materials, anti fouling (lubricating) agents, and other raw materials. It is widely used in the production and processing industry and meets the sustainability requirements of the EU's 2009 "Promotion of Renewable Energy Use Directive" RED. Obtained ISCC international certification and exported to the European Union and the United States。

Production process:

Step 1: Use used cooking oil (usually ranging from 3% to 8%) sold on the market as the main raw material, with auxiliary materials including phosphoric acid, soft water, dilute alkali solution, and alkali solution. The filter agent is diatomaceous earth, white earth, and activated carbon. The processing equipment includes conveying equipment, reaction kettle, centrifuge, high-efficiency mixer, flash tank, vertical filter, filtration mixing kettle, and deodorization tower.

Step 2: Transfer used cooking oil (usually with a content of 3% -8%) through conveying equipment to a high-efficiency mixer, where a trace amount of phosphoric acid is added and its pH value is controlled within a certain range. Heat up the high-efficiency mixer to maintain the temperature for reaction.

Step 3: Add a certain concentration of dilute alkali solution to the high-efficiency mixer, and then add a certain concentration of alkali solution while maintaining a certain temperature. Stir for a certain time through the high-efficiency mixer, and then remove water, resin, soap, and other impurities inside through a centrifuge.

Step 4: Afterwards, place the material in an efficient mixer and add a certain amount of soft water. Control the temperature for stirring. After stirring for a certain time, remove the water and impurities through a centrifuge.

Step 5: Remove excess water by placing the material in a flash tank, and then stir it in a filtration mixing kettle. Add a certain amount of clay, activated carbon, and diatomaceous earth for adsorption reaction, and then filter it through a vertical filter.

Step 6: Afterwards, it is sent into the deodorization tower and superheated steam is introduced to remove low-carbon impurities and odors through the deodorization tower. The finished product is anhydrous, impurity free, and odorless industrial grade mixed oil through a polishing bag type filter.

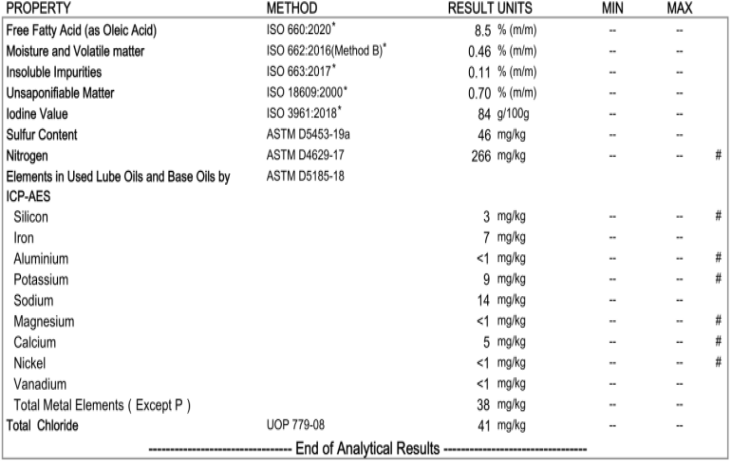

Quality Index:

+86 19113264742

Room G755, Office Building 2, Bonded Port Area, Xinying Bay District, Yangpu Economic Development Zone, Hainan Province.

09:00-18:00